THE ENGINE

“If the answer is simple, God is speaking.”

Albert Einstein

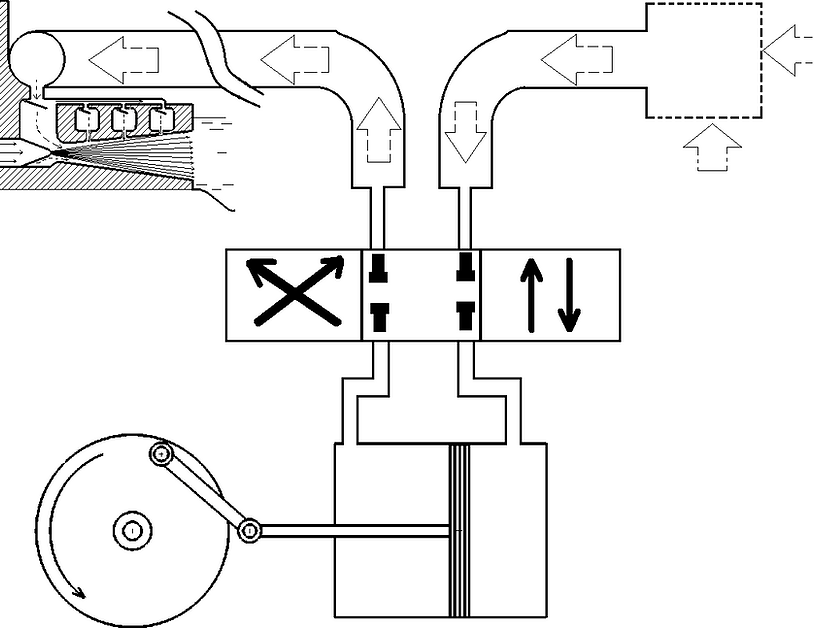

As i mentioned before, the machine is steam engine fashion with its cylinder, piston, crank-connecting rod and camshaft system, flywheel etc, the double acting cylinder allow the piston to provide power at each of its displacement, the piston works in implosion and not in expansion, as no heat needed, the system don't lose power and this increase its efficiency by comparison to the combustion engine. the loss of the efficiency depend only on friction of the piston and the leak of the cylinder.unlike a conventional turbine of a dam, the machine can be placed away from him. while operating, the engine draws air intake and becomes itself a vacuum pump. At large scale, this feature can be used to purify the air through a filter.

DAM

AIR FILTER

ENGINE

Overview of the system

before we go any further we must consider an important parameter in vacuum technology: conductance

Study of conductance: (Source: Fluid mechanics and solid applied to chemistry by Henri Faudue)

The delivery of air drawn through a pipe to the machine and then to the venturi tube (vacuum pump) leads us to study the conductance pipes because in our system, the pipes can be very long between the venturi tube and machines.

Called conductance C of a pipe (or admittance), the ratio of the flow rate measured in unit pressure by the pressure drop in the pipeline and this quantity has the dimensions of a volume flow. Conductance characterizes the ability of the pipe to the air flow and it applies to all pump components (pipe, valves, orifices etc.). Conductance is also the inverse of the resistance.

-

In series, the overall conductance will be given by:

-

In parallel, the overall conductance is given by:

effective suction rate:

The effective suction flow rate of a vacuum pump is generally lower than the nominal flow because of the conductance of the pipe (C_ca) and conductance of the orifice .In this case, the following relationship should be used.

It is therefore possible to increase the effective aspiration rate by increasing the pump flow but especially by increasing the conductance.

Expression of conductance:

The conductance of a channel actually represents the maximum gas flow which can flow in the pipe under a given pressure. Its calculation depends on the flow regime and thus the void. The venturi pump can provide only a rough or mean vacuum . For our case it is called a viscous flow as laminar. Conductance for a cylindrical pipe is equal to:

In this expression, represents the average pressure between the extremities. This equation is similar to the formula of Hagen-Poiseuille and used to determine the volumetric flow under laminar conditions. In the case of a viscous regime, the conductance within a pipe is equated to the volume flow of an incompressible fluid in laminar flow.

Expression of the conductance in the case of air:

The vacuum is usually carried out in a chamber containing air at ambient temperature, in this case the cylinder of the machine. The following simplified relationship can be used by the numerical application for air at 20 ° C:

with:

dynamic viscosity of air in Pa.s

D : pipe diameter in m

L : pipe length in m

Pm : average pressure between the vacuum pump and cylinder = P1 is usually

C: conductance in

Finally, the pipes must not suffer from any leakage.

what power we can get with this system ?

to figure it out, let's take an example and do some calculations.

assuming a huge venturi in a dam able to provide 600 m^3/s vacuum rate, depression equal to 10 000 Pa, a machine with double acting cylinder, a piston of 10 m and a stroke of 0.5 m with a poor global efficiency.

Assuming following input data:

Piston diameter: 10 m

Stroke: 0.5 m

Vacuum flow rate: 600 m^3/s

Atmospheric pressure: 101325 Pa

Partial vacuum: 10 000 Pa

Global efficiency (ƞ): 0.46 (very poor)

Output data:

Surface of the piston: 78.5398 m²

Volume of the cylinder: 39.2699 m^3

Force F = (101325 -10 000 )* 78.5398 = 717 2648.7 N = 717 264.87 daN

Work = F*stroke = 3 586 324.36 Joule

Torque = F * stroke / 2 = 1 793 162.18 Nm

Piston mean speed = Vacuum flow rate / Surface of the piston = 7.64 m/s

t = Stroke /Piston speed= 0.065449 s

Power = F*V*ƞ= 25 205 700 Watt = 25.20 Mega Watt

Pulse Frequency = Power / Torque = 14.06 rad/s

RPM= Pulse Frequency * 60 / 2π = 134.23 rpm

Efficiency VS Power

Of course the electric power will be revised downwards because of generator performance. the machine must be heavy enough to make it balanced and stable in view of the forces and inertia taking place. it does not need to turn quickly saw the torque she issued. As i said earlier, a large cylinder can be replaced by several smaller, arranged in line or V etc ...

Demonstration in small scale

This a video i uploaded on youtube, it explain and show the whole process

ROTARY ENGINE

There are different types of rotary engines that can take advantage of this system, they can be an economical alternative.

TESLA'S ENGINE

Nicolas Tesla was a genius inventor who bequeathed several inventions to us, he was also humanitarian and wanted to provide energy to all mankind. All inventors involved in energy knows him . he said before he died that his best invention is his turbine.

Born July 10, 1856 Smiljan (Kingdom of Croatia , Austrian Empire)

Death January 7, 1943 (86 years old) New York (New York, USA)

A Tesla turbine consists of a set of steel plates, with pressure nozzles applying a gas onto the edges of the discs. The gas exerts a friction disk, by a phenomenon of viscosity and adhesion of the gas boundary layer. As the gas slows and donates energy to disc, spiral towards the central exhaust. Since the rotor has no asperities, it is very robust.

Tesla turbine: concept bladeless

Tesla wrote: "This turbine is an efficient engine able to start by itself can be used as a steam turbine or mixed fluid freely, without modification of its construction and is very convenient for this. Some changes deviating from this turbine model, whenever required by the circumstances, surely offer spontaneously, but development along these general lines will certainly be considered very profitable for the owners of a steam plant while allowing the reuse of their old installation. However, the best economic results in the development of the exploitation of steam by the Tesla turbine will be obtained in specifically adapted plants. "

source: wikipedia

Tesla engine running on vacuum from youtube